Caprylyl glyceryl ether is a natural multifunctional emollient with previously demonstrated preservative-boosting effects. More recently, its pigment wetting and dispersion properties for color cosmetics and sunscreens also were identified, as shown here.

Pigments, typically in powder form, are used in cosmetics ranging from foundations and eyeshadow to lipstick, and sun and hair care products. To incorporate pigments, wetting agents can be useful, as they help to spread liquid over the solid pigment surface to enable water and oil molecules to stick to one another. Indeed, pigment wetting is the crucial first step for dispersion into a formulation. Once pigment particles are surrounded in liquid, they are dispersed and stabilized to keep them properly suspended.

Wetting agents can also impart refatting and moisturizing benefits to skin and assist in viscosity regulation. Alternately, poor pigment wetting can lead to inconsistent colors and textures, or even formulation instability.

This article explores the pigment wetting and preservative-boosting capabilities of a commercial caprylyl glyceryl ether (CGE)a. The colorless multifunctional emollient has previously demonstrated preservative-boosting effects, lowering the levels of traditional preservatives required in formulas. It also acts against malodor-causing bacteria, alone or in combination with other deodorant actives in natural deodorant formulas.1 In addition, the ingredient has been shown to improve the spreadability of formulations, providing less greasy, lighter emulsions.2

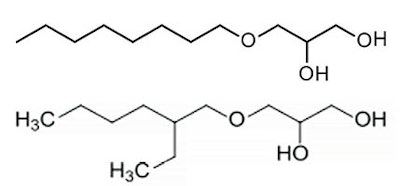

CGE is chemically similar to ethylhexylglycerin (EHG), a commonly used emollient that also boosts preservation in formulas, although CGE has a straight C8-chain, whereas EHG has a branched chain (see Figure 1, below). CGE is available from 100% renewable palm kernel oil derivatives and rapeseed raw materials, complying with DIN ISO 16128 and Natrue.3

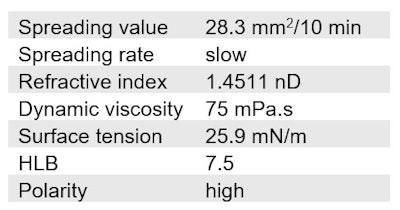

Furthermore, the biodegradable, high purity (minimum 99%) transparent liquid (at 25ºC) is stabilized with naringenin as the antioxidant, and is stable in a wide pH range of between 2 and 12 (data not shown). See Table 1, below, for additional material properties.

Based on the amphiphilic structure of CGE and its less bulky linear C-chain, compared with EHG, the authors hypothesized it could act as an effective pigment wetting agent and dispersion aid. They evaluated such using inorganic pigments commonly used in color cosmetics and sun care. In addition, two formulas containing CGE as a pigment wetting emollient were developed to demonstrate its usability and confirm its preservation-boosting properties.

Materials and Methods

Pigments and sun filters: To investigate the pigment wetting capabilities of CGE, two inorganic pigments and two mineral sun filters commonly used in color cosmetics and sun care were tested: yellow iron oxideb and red iron oxidec; and titanium dioxided and zinc oxidee.4

Experimental blends: For the pigment wetting and dispersion tests described, an approximate mixture of 65% emollient and 35% pigment was used. Caprylic/capric triglyceride (CCT) served as a benchmark emollient. To assess the impact of CGE, 1% CCT was replaced with CGE to create a 99:1 mixture of CCT/CGE as the test emollient. For a direct comparison, a 99:1 mixture of CCT/EHG was also prepared.

Experimental procedure: The emollient or emollient mixtures and respective pigments were placed in a beaker and mixed with a glass rod until the pigments were well wetted. The suspensions were homogenizedf for 2 min at 13,000 rpm. The particle sizes were measured immediately, and the viscosities were measured one day after preparing the samples.

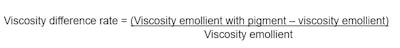

Viscosity and wetting performance: In general, the viscosity of a pigment dispersion in oil is negatively correlated with the wetting and dispersion efficacy of the dispersants. This is because reducing the attraction between particles separates them into smaller components, allowing them to move more freely. Therefore, homogenous pigment dispersions have lower viscosity, compared with nonhomogeneous dispersions.

To assess the dispersion properties of the experimental blends, the viscosities were measured by rheometer and the viscosity difference rates were calculated according to Equation 1.

Eq. 1

Eq. 1

Particle size: Pigment dispersion also was assessed using a grindometer to measure the particle sizes of the pigments, since dispersants reduce the attraction between particles to break them into smaller components. Generally, the smaller the particles in a pigment dispersion, the more stable and color intensive the dispersion.

Stability, preservation of test formulas: By design , wetting agents can influence the stability of emulsions both positively and negatively, depending on their wetting and dispersion efficacy. What’s more, CGE and EHG have previously demonstrated preservative-boosting effects, which are especially useful in color cosmetics and sunscreens, whose complexities and ingredient compositions can be difficult to protect against antimicrobial contamination during use.

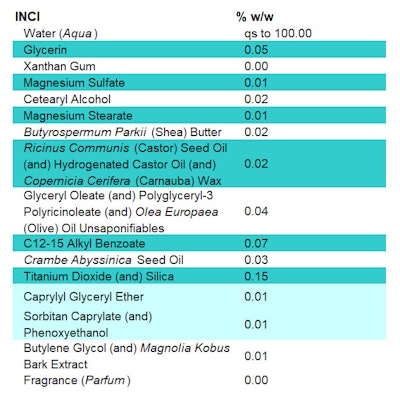

As such, two representative formulations, one tinted day cream and one sunscreen (see Formulas 1 and 2, below), incorporating CGE were developed and tested in terms of storage stability and preservation boosting.

More specifically, the day cream comprised organic UV filters and mineral pigments and provided a calculated SPF of 15 and pH between 5.0 and 5.5. It was preserved with CGE (0.5%) and a low amount of sorbitan caprylate (and) benzyl alcohol (1.2%) as the only Annex V listed preservative.

The mineral sunscreen formula incorporated TiO2 and had a pH of 7 and calculated SPF of 20. It was preserved with CGE (0.5%) and a low amount of sorbitan caprylate (and) phenoxyethanol (1.0%), with a total preservative load of 1.5%, as the only Annex V listed preservative.

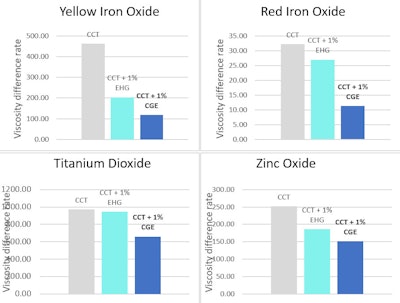

Results: Viscosity and Wetting Performance

The viscosity and wetting performance results for the test blends are summarized in Figure 1. For all pigments and mineral sun filters used, a reduced viscosity difference rate was obtained when 1% CCT was replaced by CGE. This change in viscosity indicates an interaction of CGE with the surface of the pigments. Compared with the structurally similar EHG, CGE showed better wetting performance.

Results: Particle Size

The results of the particle size measurements are shown in Figure 2, below. Compared with CCT, the addition of 1% CGE decreased the particle size of the inorganic pigments and particles. This effect was particularly strong for the yellow iron oxide, whose particles were reduced from 70 µm in CCT alone to 15 µm in the CCT and CGE blend.

Results: Storage Stability, Preservative Boosting

As noted, a tinted day cream (see Formula 1) and sunscreen (see Formula 2) were developed to test CGE in terms of wetting and dispersion stability during storage, and preservation boosting for antimicrobial stability. Both formulations were tested at room temperature, 40°C and 0°C and were found to be stable for at least eight weeks.

In addition, the day cream preserved with CGE and sorbitan caprylate (and) benzyl alcohol passed the challenge test according to DIN ISO 11930 with an A-pass. And the mineral sunscreen formula preserved with CGE and sorbitan caprylate (and) phenoxyethanol, with a total preservative load of 1.5%, passed the challenge test according to DIN ISO 11930 with A-pass.

Figures 4 and 5, below, show detailed preservation efficacy test results for the two formulations according to DIN ISO 11930. The typical five organisms, including three bacteria, one yeast and one mold, were used in the challenge tests.

For comparison, challenge testing was also conducted for the unpreserved formulations. Results showed that in their unpreserved state, the formulas failed preservative efficacy testing for almost all typical organisms, according to DIN ISO 11930.

The results confirmed that these types of formulations require a preservation system. In addition, they confirmed that efficient antimicrobial protection was obtained for all relevant organisms at low use levels of benzyl alcohol or phenoxyethanol as the only Annex V listed preservatives.

Conclusion

Previously recognized as a naturally sourced, broad-spectrum preservation booster and deodorant active, CGE is shown here to additionally support pigment wetting as well as preservation boosting, demonstrating its cross-functional utility for color cosmetics, sunscreens and other pigmented systems. Indeed, compared with structurally similar EHG, commonly used in cosmetics, it demonstrated greater pigment wetting efficacy.

Notably, preserving cosmetic formulations poses an ongoing challenge due to the prevalent trend toward natural formulations and diminishing demand for traditional preservatives. This will continually heighten the need for multifunctional ingredients and versatile preservative boosters. As such, CGE can empower formulators to surmount the green challenge and ensure robust protection for products, including those catering to the burgeoning natural cosmetics market.

a Velsan CGE (INCI: Caprylyl Glyceryl Ether) is a product of Clariant.

b Bayferrox 3920 (INCI: Yellow Iron Oxide PY42) and

c Bayferrox Rot 130 M PR 101 (INCI: Red Iron Oxide) are products of Lanxess.

d Eusolex T-2000 (CI 77891) (INCI: Titanium Dioxide (and) Alumina (and) Simethicone) is a product of Merck KGaA.

e Z-Cote (CI 77947) (INCI: Zinc Oxide) is a product of BASF Personal Care.

f Ultra Turrax, 25 mm, IKA

References

1. Zmiric, A., Fricke, T., and Johannpeter, W., Back, U. (2022, Sep). Clean beauty natural deodorant formulations. Personal Care, pp 1-5.

2. Fricke, T., Back, U. and Grohmann, J., (2021) New 100% natural booster: Velsan CGE clears up preservation issues. Pharmaceutical and Cosmetic Review, (3) pp 32-33.

3. Natrue. (Accessed 2025, Jan 6). Natrue criteria. Available at https://natrue.org/our-standard/natrue-criteria-2/

4. Deola, M. and Lionetti, N. (2023). Pigments: The Secret of Colored Products. Cosmetics & Toiletries. Available at https://www.cosmeticsandtoiletries.com/magazine/article/22793550/cosmetics-toiletries-magazine-pigments-the-secret-of-colored-products